In vertical transportation (Elevators and Escalators), technology plays a crucial role in enhancing efficiency and passenger comfort. One such innovation that has revolutionized vertical transportation systems is the Variable Voltage Variable Frequency (VVVF) controller, which became the backbone of modern Elevator technology.

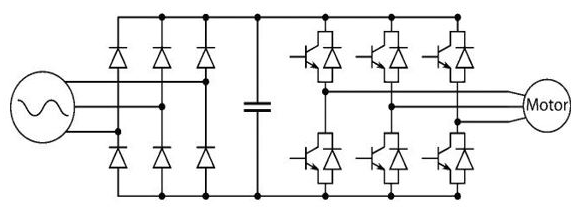

AC VVVF Elevator drive system was developed in 1983. This technology is used to control the speed and movement of Elevator by varying the voltage and frequency of the power supplied to the elevator. In this system three phase AC power is converted to DC voltage by convertor and then smoothed by electrolytic capacitor connected in parallel with the DC outputs of convertor. The smooth DC voltage is inverted by the transistor invertor into AC power of variable voltage variable frequency (VVVF) and is supplied to the motor to drive the car with variable speeds.

Riding comfort is a highly important issue, especially when high-speed Elevators are used in high-rise buildings. The Elevator systems should provide good stopping accuracy and excellent levels of riding comfort. Passengers experience problems such as vibration and jerk that occur when elevator travel between floors and while starting and stopping. To minimize the effects of these problems, the cabin must be driven in such a way as to ensure smooth operation and smooth starting and stopping. Therefore, there is a need to control the voltage and frequency of the electric motor that drives the elevator cabin.

Advantages of VVVF controller

Energy Efficiency

One of the primary benefits of VVVF controllers is their remarkable energy-saving capabilities. By adjusting the voltage and frequency based on passenger demand, these controllers help regulate power consumption and minimize wastage, resulting in significant energy savings over time. This energy efficiency makes VVVF controllers an eco-friendly choice and lowers both environmental impact and operational costs.

Smooth and quite operation

VVVF controllers’ ability to precisely control motor speed and acceleration translates into a smoother, jerk-free elevator experience. These controllers enable gentle acceleration and deceleration, minimizing passenger discomfort and ensuring a pleasant ride from start to finish.

Extended Equipment Lifespan, reduce wear and tear and maintenance cost

The precise control offered by VVVF controllers also has positive effects on elevator equipment. By reducing stress on mechanical components such as gears, brakes, and pulleys, the wear and tear associated with traditional controllers are significantly minimized. This, in turn, leads to increased longevity, fewer breakdowns, and reduced maintenance costs, benefiting both building owners and elevator service providers.

Conclusion

Variable Voltage Variable Frequency (VVVF) drive elevators are known for their efficiency, reliability, and passenger comfort, making them a popular choice for modern elevator installations.