Fundamentals of Quality Control Inspections

In my previous article, I discussed the importance of Quality Control inspections. Now, let’s dive deeper into the specific process of inspecting elevators and escalators in the VT industry. Safety and reliability are dominant in this field. A comprehensive inspection process is crucial to identify potential hazards, prevent accidents, and ensure compliance with safety regulations.

To effectively conduct these inspections, it’s essential to follow these key steps:

- Preparation (RFI)

- Awareness

- Conducting Inspection

- Reporting

- Corrective and Preventive Action (CAPA)

- Closing

- Documentation

1. Preparation

The first step in conducting an inspection is to ensure that you have the answers to the following questions:

a. What will I inspect?

It sounds like common sense but It’s essential to determine in advance what type of equipment you will inspect, such as the lift, chair lift, escalator, dumbwaiter, or home elevator, and prepare accordingly.

b. How will I inspect?

Are you planning to use a paper checklist, tablets, or online gadgets? Have you gathered all the relevant documents, including the general arrangement drawing, product manual (if required), and the printed checklist? Additionally, are there any special instructions that must be followed to complete your inspection?

c. When will I inspect?

Make sure you have allocated enough time for the inspection to avoid delays due to overlapping schedules caused by multiple inspection requests from the operation team (New Installation – NI or Modernization etc.)

2. Training or Awareness

To ensure the success of QC inspections, it’s vital to provide comprehensive training to the QC inspectors. This training should cover a range of essential topics;

- Product Knowledge

- Types of Inspections

- Inspection Procedures

- Potential Hazards

- Controls and Quality Standards

- Interpersonal Skills

By investing in comprehensive training, organizations can empower their QC inspectors to conduct effective inspections, identify potential issues, and ensure product quality.

3. Quality Control Inspections (Patrolling vs. RFI-Based)

Quality Patrolling:

- Purpose: Proactive monitoring of project activities to ensure adherence to quality standards and procedures.

- Process:

- QC inspectors visit job sites randomly at various stages of the project.

- They assess ongoing work, materials, and equipment.

- They identify any deviations from quality requirements or best practices.

- They provide immediate feedback to the responsible parties.

RFI-Based Inspections:

- Purpose: To address specific quality concerns or requests raised by the operational teams.

- Process:

- Operational teams submit a Request for Inspection (RFI) to the QC department.

- The RFI plans the specific activity for inspection.

- QC inspectors conduct a targeted inspection based on the RFI.

- They provide a detailed assessment and recommendations.

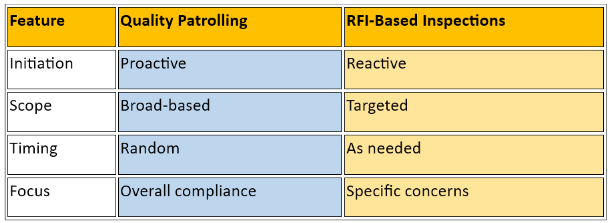

Key Differences:

Benefits of Both Types:

- Quality Patrolling:

- Early detection of issues

- Continuous improvement

- Enhanced project quality

- RFI-Based Inspections:

- Addresses specific concerns

- Provides targeted feedback

- Supports decision-making

By effectively utilizing both quality patrolling and RFI-based inspections, organizations can ensure that their projects meet the highest quality standards and minimize risks.

4. Reporting

After the inspections the most important thing is to prepare the report and forward it to the concerned supervisor or engineer for taking action like defects repair, fixing the issues and for corrective and preventive actions.

Specific Guidelines for QC Reports:

Major vs. Minor Observations: Clearly categorize observations based on their severity.

Image Usage: Include relevant images to visually illustrate defects or issues.

Report Structure: Consider using a structured format with sections for,

- Introduction

- Findings (major and minor observations)

- Recommendations

- Conclusion

Distribution: Forward the report to the relevant installation supervisor or engineer for action.

Key Elements of a QC Report:

- Clarity and Conciseness: Use clear and concise language to convey information effectively.

- Image Quality: Capture high-quality images that are well-lit, focused, and unblurred.

- Image Organization: Arrange images logically, using columns or sections as needed.

- Image Annotation: Clearly label images with relevant information (e.g., location, defect type).

- Consistency: Ensure consistent image size, orientation, and labeling.

- Accurate Terminology: Use industry-specific terms correctly to avoid misunderstandings.

- Proper Formatting: Adhere to a standardized report format for easy readability and reference.

- Targeted Distribution: Identify the appropriate recipients (To and Cc) for the report.

5. Corrective and Preventive Action (CAPA)

Corrective and Preventive Action (CAPA) is an essential process in Quality Control (QC) to address non-conformities and prevent their recurrence. When the installation team receives a report from QC inspectors, they should initiate a CAPA process to resolve the reported observations. Once the corrective actions have been implemented, the installation team should prepare a rectification report. This report should detail the actions taken, the evidence of rectification (e.g., photos, inspection results), and any preventive measures put in place. The report should then be submitted to the QC inspectors for review and closure.

By effectively implementing CAPA, organizations can improve their quality processes, reduce non-conformities, and enhance overall customer satisfaction.

6. Closing

The closing process is a critical step in any QC inspections. It ensures that the identified issues have been addressed and the process is complete. There are two primary methods for closing the inspection reports.

For reports with major observations that pose safety or quality risks, a re-inspection by the QC team is necessary to verify that the rectification work has been done correctly and effectively. However, for minor issues or observations, rectification images can serve as sufficient evidence, eliminating the need for a site revisit.

The closing process should be carried out promptly to ensure that any necessary corrective actions are taken in a timely manner. Delays in closing reports can lead to ongoing quality issues or safety hazards.

7. Documentation

Regardless of the closing method, it is essential to maintain clear and comprehensive documentation of the rectification process. This includes the

- original report

- rectification images

- additional correspondence or re-inspection reports

By adhering to this structured approach, QC inspectors can play a vital role in ensuring the safety and reliability of elevators and escalators and maintained the quality standards throughout the project in the VT industry.