Breakdown FREE Elevators

Can we have breakdown FREE elevator operations?

It’s a million-dollar question for the elevator owners and users. It sounds funny, but not impractical or impossible.

To enjoy a healthy human body, one needs to have a controlled diet, regular exercise, and regular medical check-up.

Similarly, to enjoy breakdown free elevator operations one needs to take care of the elevator servicing, adjustments, timely replacement of worn-out parts, proper usage, and surrounding conditions and regular performance and safety audit.

If we study the possible reasons for the breakdown, we can easily control the breakdowns and even can have break down free operations.

Let us first study the possible reasons for elevator breakdowns or failures.

1-Voltage fluctuations or power failure.

Supply voltage issues, loose connections, earthing issues can create breakdowns.

Ensure that all the power connections are properly done. The earth wire connection is also made properly.

These types of issues are generally noticed in new buildings, under construction sites.

2-Dust accumulation.

If dust gets accumulated on Door contact, or relay contact, can create breakdowns. If the door tracks get dust or some small material piece, it can create problems in door closing leading to breakdown.

The door safety screen is a very sensitive one and if dust gets accumulated on it, this can also add to the breakdowns.

It is advisable to use a blower to remove dust from the parts and door track.

These types of issues are generally noticed in building where some repair work or furniture work is going on.

3-No timely Servicing.

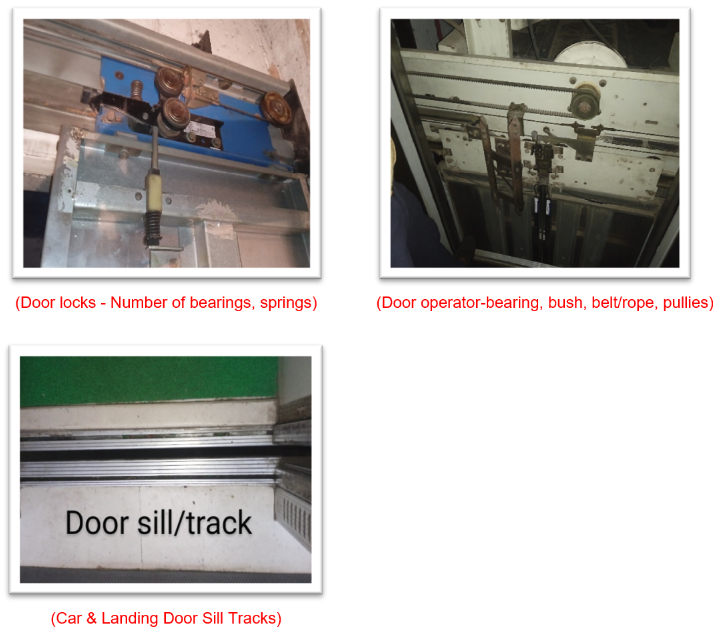

Elevators have a number of moving parts. Each part needs regular oiling, greasing and setting. Door operator and door itself has a maximum number of moving parts. Some parts work with spring tension effect, like door locked contact, lock lever, door weight, door pick up mechanism. All these springs need to be checked and adjusted regularly to maintain proper tension.

There are a number of bearings used in the elevators mainly in the door operators and door locks. These also need to be checked regularly and maintained properly to ensure trouble free operations.

4-No proper Adjustment/setting.

All the moving parts need regular setting. These includes:

- Door mechanism

- Door locks

- Brake

- Rope tension

- Over Speed Governor

5-Variations in Temperature around the control panel.

The controller components are designed to perform within a predefined temperature range. If the temperature goes beyond that then it may start misbehaving. It is advisable to maintain the machine room temperature as recommended by the supplier.

Particularly hydraulic lift oil pressure is much affected by temperature variations.

Ensure that proper cooling and ventilation is provided in the machine room.

6-Change in Humidity.

Humidity also affects the performance of some components. Touch button operations are much affected with the increase in humidity.

7-Handling by the users.

You will find advice in the elevator cabin mentioning do and don’ts. That is a very common practice.

In addition to that some extra precautions are suggested to ensure trouble free operations.

Bad handling or wrong handling adds to the problems, it looks very simply but is neglected or overlooked many a times.

For example, holding the door when it is closing, pressing the call buttons repeatedly and with force, jumping inside the moving cabin, pressing unwanted buttons, overloading the elevator, all these can add to the breakdowns.

Carrying materials specially when some repair work or furniture work is going on also increases the possibility of breakdowns.

Proper instructions and checks during such work can avoid unwanted breakdowns.

These are simple pieces of advice but are the outcome of long experience and in-depth study of the industry. If followed properly it can easily reduce the frequency of elevator breakdowns.

Create awareness among the users on a regular basis and witness the results.